Large openings in a composite concrete slab are traditionally framed by trimming steels, which not only provide bearing for the surrounding metal deck but also enable steel edge trims to be used to form the edges of the slab. It’s not always practical, however, to provide trimmers for small voids such as service holes, but these can be accommodated provided certain rules are followed.

Voids with no trimmers are formed by boxing out to the required dimensions and then cutting the deck within once the slab has cured. A bond will have been formed between the deck and the concrete so it’s important that a non-percussive method of cutting (such as diamond core drills or saws) is used to preserve the composite nature of the structure.

Figure 5.6a below shows typical methods of boxing out voids with no trimming steel, using timber formwork or a pre-formed block.

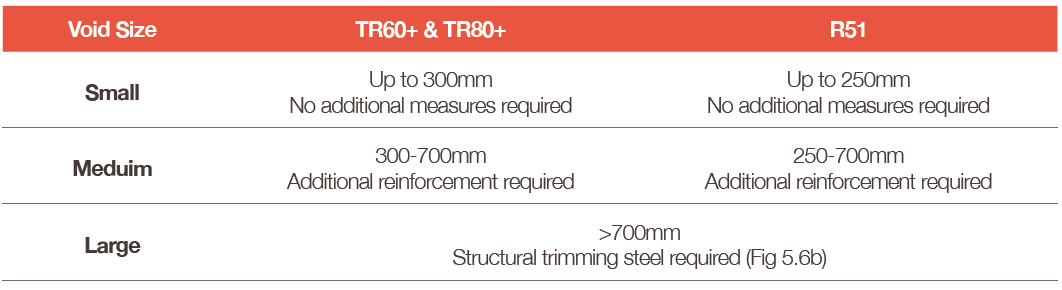

Although they are all classed as “small”, openings with no trimmers can be categorised by size, becoming either small or medium (see the table below). The dimensions of each are also dependent on the deck profile through which they pass.

This table and associated guidelines can be found in section 15.6 ‘Forming service holes’ on SMD’s TGN Online

It’s important to note that these figures refer to the dimensions across the profile, ie perpendicular to the span of the deck. Ideally service voids should be square or circular, but if this is not possible then the length (the dimension parallel to the deck span) can be greater. The only limit for the length in this case is one quarter of the span itself.

The project structural engineer is responsible for designing the additional reinforcement required for the medium sized service voids. This should generally be in accordance with BS EN 1992-1-1 or BS8110 and a typical example of a void trimmed by steel reinforcement is shown in Figure 5.6b in our TGN Online. Guidance on the design of trimming reinforcement is also available in Section 4.2.6 of the SCI Publication P300 (Composite Slabs and Beams Using Steel Decking: Best Practice for Design and Construction).

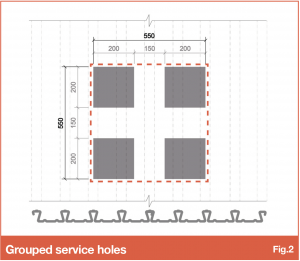

Some recent queries received by our Technical Department relate to situations in which holes are required to be in groups. Service penetrations are only considered to be in isolation if they are more than either 666mm or 1.5 x the void width apart, whichever is the greater. Where a number of them are grouped closer than this (transverse to the deck span), they should be treated as one larger void. For example, 4No. 200mm x 200mm holes, 150mm apart in a square formation would be considered as one medium sized void 550mm wide, as shown in Figure 2.

There are a number of other factors to consider when designing service penetrations through the slab.

- Removing a section of any deck span may affect the span condition in adjacent bays.

- High concentrated loads should not be applied near the void locations.

- When designing circular voids that are to be core-drilled through the deck and cured slab, the proximity to composite beams and location of any slab reinforcement must be considered.

- Suitable fire-stopping methods should be considered.

- Cutting the deck before the concrete is poured is not recommended as this is likely to result in a reduction of the flexural capacity of the deck and cause excessive deflection, which can further lead to concrete ponding or even collapse.

Health and Safety is a critical consideration in the formation of any holes through the slab, large or small. Objects can be dropped through small openings and larger ones of course present a fall-from-height risk. This can be mitigated by various protection systems, including the erection of handrailing, but all of these require the input of additional trades, create obstructions and can have an impact on programme for their erection and dismantling.

As an alternative, we can offer the VoidSafe™ Protection System, a non-slip composite Glass Reinforced Plastic (GRP) floor grating system that is designed, supplied and installed on a specially designed edge trim by SMD together with the metal deck operations. VoidSafe™ is durable, lightweight and chemical/ corrosion resistant and can be left in place post construction, easily accommodating individual service ducts.

Further information on our VoidSafe™ Protection System can be found in Section 13.3 on TGN Online and also in pdf format.

Further Technical Guidance from SMD

See section 15.6 ‘Forming service holes’ on SMD’s TGN Online (Technical Guidance Notes) and the SMD Technical Team will happily assist with further recommendations and designs to suit your bespoke circumstances.