It’s no secret that the construction industry has one of the highest risk factors for injury or fatality, so it’s up to all of us to create solutions to make it safer for all.

As a building takes shape there are often holes or voids in the floor which could mean that there’s a significant risk of not only on-site workers falling, but also that equipment, tools or materials could be accidentally dropped.

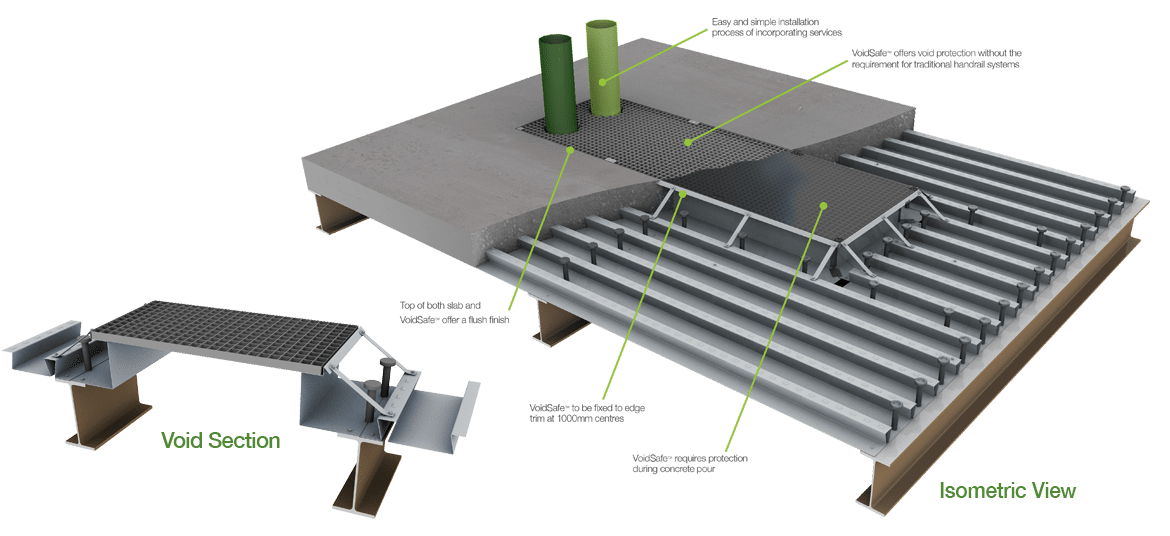

Our solution to this is the VoidSafe™ Protection System – non-slip decking that can be quickly and easily installed and with no need to take it down after the programme is complete, it means that it can become part of the finished build. This glass reinforced plastic (GRP) has become increasingly popular throughout the construction industry, but is finding its place in the marine, rail and M&E services sector too.

Partnering with the Nottingham University engineering department to ensure that the materials used are compliant, we’ve created a safety solution that will help to save time, money and effort as well as keeping not only our installers safe, but also other trades on site throughout the entire build.

More cost effective than handrails or scaffolding.

Although traditionally sites would address hole protection with the installation of system handrails or scaffolding, these can actually become more expensive in terms of both time and cost when adaptions and re-configuration changes, as well as constant inspections throughout the programme are all factored in.

Planning to use our VoidSafe™ Protection System right from the start of the planning process can help to alleviate some of this time, resource and money pressure as there is no need to move handrails time and time again for following trades. This also eliminates the need for further coordination and visits from the handrail providers which all comes with an extra cost.

How is VoidSafe™ installed?

We’ve been offering VoidSafe™ for a number of years now and will install it at the same time as the floor deck using the same expertly trained operatives – so it’s all done and dusted without having to wait for an additional supplier to come and fit handrails. What’s more, it can be left in place at the end of the build and become integrated into the structure, rather than having to factor in time for someone to come and take it down like you would with handrails.

With savings in cost, time and resource it’s clear to see why our VoidSafe™ Protection System has become popular with many of our clients. We’ve also seen a really positive reaction from other trades who feel that it means that not only do they have more freedom to move around at height without handrails in the way, but it feels much safer too.